The expertise offered by Pennsylvania College of Technology and its acclaimed Plastics Innovation & Resource Center attracted an array of plastics professionals to campus for the recent Extrusion Seminar and Hands-On Workshop.

Individuals representing 22 companies from 10 states, Canada and Italy attended the 21st annual event that featured extrusion experts Chris Rauwendaal, president of Rauwendaal Extrusion Engineering Inc., and Kirk M. Cantor, professor of plastics and polymer technology.

“Having world-class experts such as Kirk and Chris is extremely valuable,” said Ryan Antoniadis, CEO of Plastifab Industries in Saint-Laurent, Quebec. “They provide great insight and practical ideas to take back to our organizations in our journey of continuous improvement.”

Rauwendaal has more than 40 years of extrusion experience. He holds several patents and has written more than 90 articles on extrusion, as well as five books. Cantor has taught extrusion for 33 years, the past 29 at Penn College. He co-developed two courses with Rauwendaal and authored a book: “Blown Film Extrusion.” The third edition was released in December by Hanser Publications.

Rauwendaal has more than 40 years of extrusion experience. He holds several patents and has written more than 90 articles on extrusion, as well as five books. Cantor has taught extrusion for 33 years, the past 29 at Penn College. He co-developed two courses with Rauwendaal and authored a book: “Blown Film Extrusion.” The third edition was released in December by Hanser Publications.

In addition to Cantor, Penn College facilitators included Brennan B. Wodrig, PIRC program manager; Christopher J. Gagliano, PIRC project manager; Timothy E. Weston, associate professor of plastics and polymer technology; Adam C. Barilla, instructor of plastics and polymer technology; Gary E. McQuay, part-time instructor of plastics and polymer technology; and student research assistants Spencer L. Cotner, of Muncy, and Brandon B. Zechman, of Granville Summit, both of whom are plastics and polymer engineering technology majors.

Shannon M. Munro, vice president for workforce development, opened the session by thanking the event’s sponsor – George Fischer Harvel.

“We are able to offer the best programming possible to the extrusion community with the generous support of our corporate sponsor, GF Harvel,” Munro said. “We are fortunate to have sponsors for our events that understand the importance of furthering the knowledge in the field.”

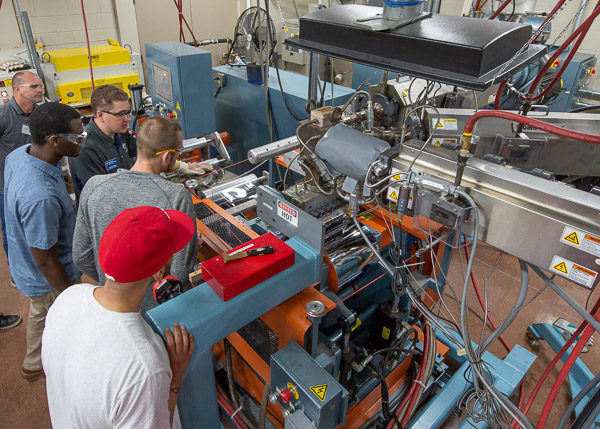

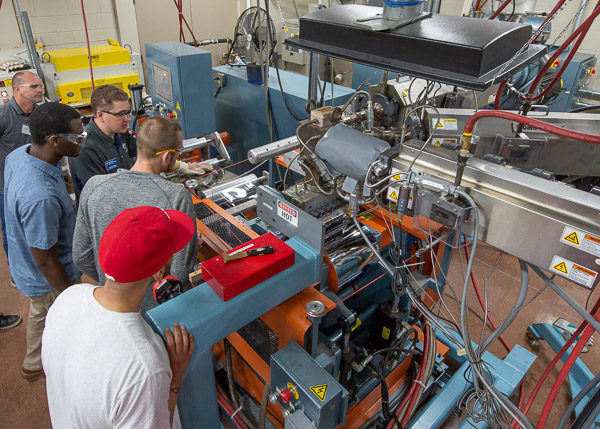

The workshop covered several extrusion topics in a multimedia format and offered extensive training on industry equipment. The combination of theory and hands-on practice generated rave reviews from participants.

“Awesome lectures and high-quality lab classes,” said Raymond Moyer Jr., lead extrusion operator for Cardinal Systems in Schuylkill Haven.

“Great way to visualize and experience extrusion processes that I was not familiar with,” said Michael Swenson, extrusion engineer for Plastic Ingenuity in Mazomanie, Wisconsin.

“The hands-on workshops helped by providing me with a different point of view on how to apply the science of extrusion into everyday operations, making me a more knowledgeable technician,” added James Karanja, a technician for B. Braun Medical in Allentown.

The PIRC – celebrating its 25th anniversary – is one of the top plastics technology centers in the nation for research, development and education related to injection molding, extrusion, blow molding, rotational molding and thermoforming. To learn more, call 570-321-5533.

Penn College is one of six institutions nationwide offering plastics degrees that are accredited by the Engineering Technology Accreditation Commission of ABET. In addition to the bachelor’s degree in plastics and polymer engineering technology, students may seek an associate degree in plastics and polymer technology.

Information about those majors and other programs offered by the college’s School of Industrial, Computing & Engineering Technologies is available by calling 570-327-4520.

For more on Penn College, a national leader in applied technology education and workforce development, email the Admissions Office or call toll-free 800-367-9222.

Individuals representing 22 companies from 10 states, Canada and Italy attended the 21st annual event that featured extrusion experts Chris Rauwendaal, president of Rauwendaal Extrusion Engineering Inc., and Kirk M. Cantor, professor of plastics and polymer technology.

“Having world-class experts such as Kirk and Chris is extremely valuable,” said Ryan Antoniadis, CEO of Plastifab Industries in Saint-Laurent, Quebec. “They provide great insight and practical ideas to take back to our organizations in our journey of continuous improvement.”

Rauwendaal has more than 40 years of extrusion experience. He holds several patents and has written more than 90 articles on extrusion, as well as five books. Cantor has taught extrusion for 33 years, the past 29 at Penn College. He co-developed two courses with Rauwendaal and authored a book: “Blown Film Extrusion.” The third edition was released in December by Hanser Publications.

Rauwendaal has more than 40 years of extrusion experience. He holds several patents and has written more than 90 articles on extrusion, as well as five books. Cantor has taught extrusion for 33 years, the past 29 at Penn College. He co-developed two courses with Rauwendaal and authored a book: “Blown Film Extrusion.” The third edition was released in December by Hanser Publications.In addition to Cantor, Penn College facilitators included Brennan B. Wodrig, PIRC program manager; Christopher J. Gagliano, PIRC project manager; Timothy E. Weston, associate professor of plastics and polymer technology; Adam C. Barilla, instructor of plastics and polymer technology; Gary E. McQuay, part-time instructor of plastics and polymer technology; and student research assistants Spencer L. Cotner, of Muncy, and Brandon B. Zechman, of Granville Summit, both of whom are plastics and polymer engineering technology majors.

Shannon M. Munro, vice president for workforce development, opened the session by thanking the event’s sponsor – George Fischer Harvel.

“We are able to offer the best programming possible to the extrusion community with the generous support of our corporate sponsor, GF Harvel,” Munro said. “We are fortunate to have sponsors for our events that understand the importance of furthering the knowledge in the field.”

The workshop covered several extrusion topics in a multimedia format and offered extensive training on industry equipment. The combination of theory and hands-on practice generated rave reviews from participants.

“Awesome lectures and high-quality lab classes,” said Raymond Moyer Jr., lead extrusion operator for Cardinal Systems in Schuylkill Haven.

“Great way to visualize and experience extrusion processes that I was not familiar with,” said Michael Swenson, extrusion engineer for Plastic Ingenuity in Mazomanie, Wisconsin.

“The hands-on workshops helped by providing me with a different point of view on how to apply the science of extrusion into everyday operations, making me a more knowledgeable technician,” added James Karanja, a technician for B. Braun Medical in Allentown.

The PIRC – celebrating its 25th anniversary – is one of the top plastics technology centers in the nation for research, development and education related to injection molding, extrusion, blow molding, rotational molding and thermoforming. To learn more, call 570-321-5533.

Penn College is one of six institutions nationwide offering plastics degrees that are accredited by the Engineering Technology Accreditation Commission of ABET. In addition to the bachelor’s degree in plastics and polymer engineering technology, students may seek an associate degree in plastics and polymer technology.

Information about those majors and other programs offered by the college’s School of Industrial, Computing & Engineering Technologies is available by calling 570-327-4520.

For more on Penn College, a national leader in applied technology education and workforce development, email the Admissions Office or call toll-free 800-367-9222.