Faculty Member Brings Shipyard Experience Into Welding Lab

Tuesday, November 18, 2014

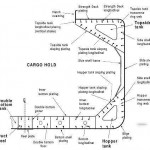

Benefiting from the real-world experience of an alumnus turned faculty member, Penn College students are simulating how the watertight bulkhead of an oil tanker is assembled, welded and pressure-tested. "Often times, the day-to-day lab projects we do in class can become very monotonous, and leave students asking, 'Is this really what it's like out in the field?'and "When am I ever actually going to need to do this?'" said Steven J. Kopera, a welding lecturer in the School of Industrial, Computing & Engineering Technologies. Kopera earned degrees in welding technology (2007) and welding and fabrication engineering technology (2009) before embarking on a career that included time at the Aker Philadelphia Shipyard. While course work provides necessary practice in fundamentals and technique, he said, it is done under the most ideal circumstances – conditions that are atypical of industry. "The intent behind this project was to get the students out of their routine and their comfort zone," he said, "and to expose them to a situation that they will be faced with in the workforce." Kopera has been brainstorming the exercise for some time and, with only seven students in his unusually small class this semester, the time was right. He explained how hull sections are put together and showed them various pictures and sketches in the classroom, supplementing the instruction with stories of his "overwhelming" encounters as a young welder newly exposed to large-scale fabrication. "This project will apply those skills they have been honing to a realistic industry scenario," Kopera said. noting that they will be using the flux-core, arc-welding process that they have been learning in lab. "I believe it will not only be a good learning experience for them, but also a testament to how well our normal class routine prepares them for an actual on-the-job application." Having fashioned a small mock-up of a watertight bulkhead, the students plan to do the welding and pressure-testing on Thursday.

Benefiting from the real-world experience of an alumnus turned faculty member, Penn College students are simulating how the watertight bulkhead of an oil tanker is assembled, welded and pressure-tested. "Often times, the day-to-day lab projects we do in class can become very monotonous, and leave students asking, 'Is this really what it's like out in the field?'and "When am I ever actually going to need to do this?'" said Steven J. Kopera, a welding lecturer in the School of Industrial, Computing & Engineering Technologies. Kopera earned degrees in welding technology (2007) and welding and fabrication engineering technology (2009) before embarking on a career that included time at the Aker Philadelphia Shipyard. While course work provides necessary practice in fundamentals and technique, he said, it is done under the most ideal circumstances – conditions that are atypical of industry. "The intent behind this project was to get the students out of their routine and their comfort zone," he said, "and to expose them to a situation that they will be faced with in the workforce." Kopera has been brainstorming the exercise for some time and, with only seven students in his unusually small class this semester, the time was right. He explained how hull sections are put together and showed them various pictures and sketches in the classroom, supplementing the instruction with stories of his "overwhelming" encounters as a young welder newly exposed to large-scale fabrication. "This project will apply those skills they have been honing to a realistic industry scenario," Kopera said. noting that they will be using the flux-core, arc-welding process that they have been learning in lab. "I believe it will not only be a good learning experience for them, but also a testament to how well our normal class routine prepares them for an actual on-the-job application." Having fashioned a small mock-up of a watertight bulkhead, the students plan to do the welding and pressure-testing on Thursday.Photos provided