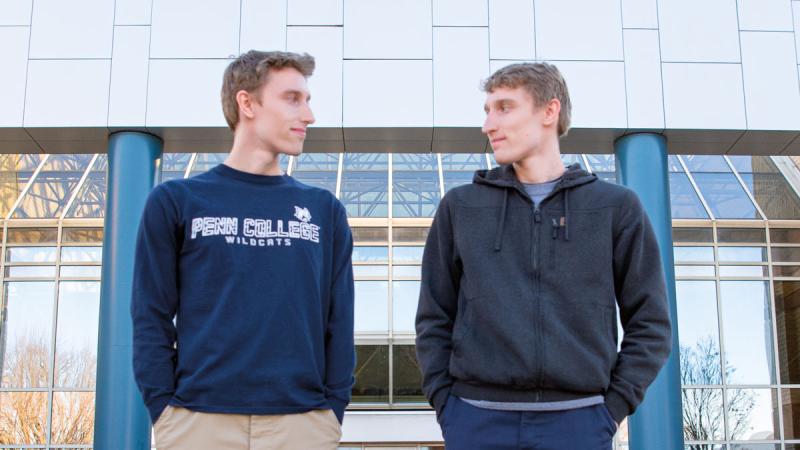

Jon (left) and Jake Twardowski enhance their hands-on education on the college’s hybrid thermoforming machine.

Two of a kind | Twins follow duplicate Penn College paths

Published 09.06.2024

by Thomas Speicher

Writer/Video Producer

LONG BEFORE THEY TEAMED TO MELT PLASTICS IN THEIR MOTHER’S TOASTER OVEN, Jake T. and Jon J. Twardowski wished to study polymers at Pennsylvania College of Technology. Their teenage science experiments mixing a glue gun and the toaster oven eventually ruined the appliance but not their dream. About eight years later, the brothers hold bachelor’s degrees in polymer engineering technology.

The straight-A students graduated from Penn College in May before embarking on their desired careers in the plastics industry.

“They stand out as two of the top students I have taught in over 34 years; certainly they’re in the top 10,” said Kirk M. Cantor, professor of plastics and polymer technology. “Not only did they perform academically at the highest level, but they both learned very quickly and gained a deep understanding of even the most challenging topics I presented.”

The matching success of Jake and Jon shouldn’t surprise. They are mirror-image identical twins, meaning defining characteristics or physical traits, such as a dominant hand, of one are on the opposite side of the other. Put simply, when the brothers look at each other, it’s as if they are staring in a mirror.

That fact is appropriate, considering the achievements of one are a perfect reflection of the other’s success.

“They have been so alike, that at times, it has been mind-blowing,” said their mom, Jan, a full-time assistant specializing in applications and data control in the college’s Admissions Office.

They have been so alike, that at times, it has been mind-blowing.

Sure, Jon is slightly taller than Jake’s 6-foot-1 frame. Jake sweeps his bangs to the side, whereas Jon pushes his up. Jon prefers slightly dressier attire than Jake’s cargo trousers and Adidas track jacket. Jake is a bit reserved compared to Jon. And Jon likes coleslaw more than Jake does. But other than those examples?

“Overall, they are very similar in their likes and dislikes,” Jan said. “They have always been close and do seem to enjoy doing like-minded things. Whether they were building forts, playing computer games, or making and operating their blacksmithing setup, they almost always did it together.”

Yes, blacksmithing.

“We had a fantastic metal shop teacher in high school who encouraged students to pursue their own projects. We built an open-air workshop with our dad. Its design enabled us to forge while being protected from rain and snow,” Jon explained.

“We built the home forge and bellows out of scrap material, which we later replaced with a more ergonomic and efficient design,” Jake said. “I primarily created knives and assorted tools, and my brother focused on making jewelry.”

Blacksmithing was the latest manifestation of the twins’ tinkering and innate curiosity.

“Ever since I was a kid, I’ve been either building things or breaking things. Being hands-on is certainly the most effective way to learn, and it also happens to be the most fun,” Jake said.

Jon traces such fun back to their days as young boys playing with Lego bricks. The plastic building blocks provided endless hours of stimulation and sparked the brothers’ interest in polymers. Whether contemplating designing their own bricks or watching YouTube videos on plastics projects, the twins were hooked. Eventually, they progressed from building with Legos to creating rudimentary plastic holiday ornaments out of milk jugs and laundry detergent bottles.

Their maker-culture instincts led them to not only embrace plastics but also Penn College. That was clear in eighth grade when they were assigned to write a letter to their senior selves. The boys expressed duplicate goals. Jon and Jake wrote that they hoped to be pursuing a plastics degree at Penn College.

With that objective achieved, the twins know their eighth-grade selves made the right choice in terms of career field and colleges.

“It is an interesting and flexible career path,” Jake said.

“The plastics industry is paramount for the function of our modern world,” Jon expanded. “Plastics are an incredibly versatile material that is utilized every day in practically every industry. The plastics program at Penn College provides an invaluable experience for anyone looking to enter this field.”

Parts are processed on the college's roll-fed thermoformer (also called a thin-gauge thermoformer). Equipment in Penn College's Thermoforming Center of Excellence is used to teach polymer engineering students and incumbent workers and supports industry research and development projects through the college's Plastics Innovation & Resource Center.

Growing up in Williamsport, the brothers were quite familiar with the school. Jan began working at the college part time in 2010 and along with her husband, John, would bring the boys to campus for computer fairs and open houses.

“As a middle-schooler, touring Penn College exposed me to a myriad of technologies and equipment that were completely new to me,” said Jon, who is the older brother by nine minutes. “The experience made me feel incredibly enthused about the possibilities of my future.”

Jake remembers being impressed by the beauty of campus and the “unique-looking buildings.” The joy of playing video games in the Bush Campus Center and munching on free food are mixed in the memories as well. “Penn College just kind of became my college of choice. I never really considered going to any other college,” he said.

Penn College’s distinction as one of just seven institutions nationwide offering polymer degrees accredited by the Engineering Technology Accreditation Commission of ABET was a bonus.

“That leaves graduates of the program with a unique and in-demand degree, and a job market seeking people with these specialized skills,” Jake said.

Based on the college’s data from 2017- 22, the overall job placement rate for graduates of the polymer engineering technology major is 100%.

While in high school, the brothers prepared for Penn College by completing an introduction to plastics dual-enrollment class. Of course, they both received As. That symmetry would continue for the next four years in college: matching classes and high grades.

“We grew up in the same environment, which makes our thought process similar. We studied and reviewed together most of the time, so we usually achieved comparable grades,” Jake noted.

“Studying for exams together practically ensured that we each shared the same understanding of the content,” Jon said. “We are not very competitive. I would rather see us both succeed at something than for one to triumph over the other. We tend to help each other out and encourage each other to do our best.”

Their best resulted in perfect 4.0 GPAs, successful internships, and induction into the honor societies of Phi Theta Kappa and Alpha Chi. (High academic achievement runs in the family. The twins’ older sister, Jenny, is completing her doctorate in biochemistry and molecular biology at the University of Rochester.)

“A 4.0 is not a small accomplishment. Our students are routinely carrying 16- to 18-credit semesters to graduate on time. That’s a lot of work and a lot of time dedicated to making sure everything you turn in is as close to perfect as you can get it,” said Vii J. Rice, instructor of plastics and polymer technology and co-department head. “To get through all eight semesters without slipping is a testament to their intelligence but also their endurance and drive.”

A 4.0 is not a small accomplishment. That’s a lot of work and a lot of time dedicated to making sure everything you turn in is as close to perfect as you can get it.

“They have everything an employer is looking for: intelligence, dedication to the task at hand, respect for and the ability to get along with others, desire and ability to learn, and excellence in performance,” Cantor echoed. “They are also very nice young men.”

The brothers returned the compliments. “From early on in my college education, I could tell that the instructors at Penn College truly want their students to succeed,” Jon said.

“The instructors have all been excellent at teaching their content and aiding students however they can. This is very important for academic success!” Jake stressed.

Both also applauded the hands-on nature of the polymer engineering program, which requires experience with all the major plastics processing methods. Not surprisingly, Jon and Jake identified the same process – injection molding – as their favorite for the identical reason: short cycle time.

But graduation has taken them on different paths in terms of employers and locations for their burgeoning careers as process engineers. Jake is at the Azek Co., a manufacturer of sustainable outdoor living products in Wilmington, Ohio, and Jon works for West Pharmaceutical Services in Williamsport. West designs and manufacturers integrated containment and delivery systems for injectable medicines.

Twins Jon (left) and Jake Twardowski outside of Penn College’s Breuder Advanced Technology & Health Sciences Center, home of the polymer engineering technology program. They both earned bachelor’s degrees in polymer engineering technology – and 4.0 GPAs – in May.

Their summer 2023 internships – Jake worked for Azek in Scranton and Jon interned at Tekni-Plex Healthcare in New Hampshire – provided a taste of the separation ahead. However, that was a matter of weeks. Their separation as professionals could be years.

“Will this cause some heartache and tough emotions? Probably. But do I think they are going to let that stop them? Absolutely not,” Rice said. “They did not get to take their exams together, their practicals together or their internships together, but they knocked all of those out of the park. It has been a slow build over the last four years, but I believe they have been preparing for this moment and will succeed wherever they may end up.”

The twins estimated they talked four times a week during their separate summer internships. Their mother countered that the two communicated daily.

“Sometimes I was told that one couldn’t talk to me for very long because he was all talked out from talking to his brother,” she said. “If one hadn’t heard from the other by a certain time, usually around 5:30 or 6, I would get a call or text asking if I knew what was going on with the other one.”

Jan expects that to be the case going forward. “I know there will be a lot of talking between them. I am positive they will be in constant communication,” she said. “As a mom, I have been blessed. It is great seeing your kids get along and be each other’s best friend!”

And when reunited at home, they can work together to fix that infamous toaster oven.

“We just called it a science experiment and moved on,” Jan laughed. “I am pretty sure they still have it down in the basement.”

Share your comments

Penn College Magazine welcomes comments that are on topic and civil. Read our full disclaimer.

We love hearing from you