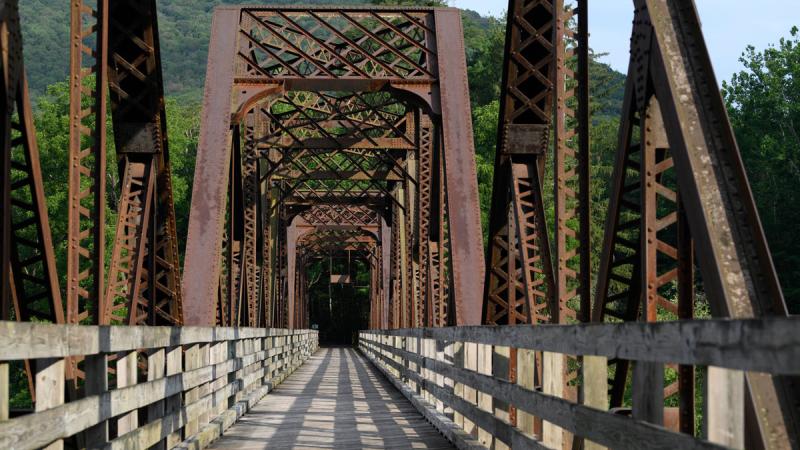

Reagan McCoy '20 strides across a stream during the Eastern States 100. The 100-mile trail race features 20,000 feet of elevation gain. [Photo courtesy of Kevin Peragine Photography]

Ultra-Impressive

Published 02.16.2024

by Jennifer Cline

Writer/Magazine Editor

Grad Wins 100-Mile Ultramarathon

In a feat that defies the average imagination, Pennsylvania College of Technology grad Reagan McCoy not only completed, but won – by 35.5 minutes over the second-place finisher – the Eastern States 100, a 100-mile ultramarathon trail race that starts and finishes in Little Pine State Park, about 30 miles from Penn College’s Williamsport campus.

On the Penn College campus, McCoy ’20 was part of the cross-county team and prepared for his current work as a process engineer for Advanced Powder Products Inc. by completing a bachelor’s degree in plastics & polymer engineering technology.

At the Eastern States 100, McCoy crossed the finish line in 22 hours, 23 minutes and 58 seconds. He and 130 other finishers from across the U.S. and beyond outlasted not only a full day and night (and day again, for many, with a 36-hour cutoff to finish the race) on their feet, but steep terrain and rain that made for fast-moving water when the course had them cross Pine Creek.

“I’m glad we didn’t know about that ahead of time,” said his father, Steven K. McCoy, an external records evaluator in the college’s Registrar’s Office, who said he and his wife were battling sleeplessness even without knowledge of a water crossing.

The elder McCoy recalls, with humor, his son’s first venture into running: a 2-mile route to earn a Boy Scout badge. After some teasing from a passing car, he told his father, “I’m never doing that again.”

Turns out, he loves it. Here, McCoy explains why.

How did you start running?

During my senior year of high school, I used to lift weights with one of my friends after class. He was an active runner and one day talked me into going for a run. It was rough, but after a few months I was able to run a couple of miles at a time. I went out for track that year, which was unconventional to start a new sport as a senior, but I loved it. I continued to run for the next few years and had friends that introduced me to trail running. I signed up for the cross-country team at Penn College to improve upon my trail running and learned how to train smart and effectively, and it totally transformed my running abilities.

Why do you love it?

For one, it’s the easiest and most effective way to get exercise. The world is your gym and no membership is required. Additionally, it gives me mental clarity, focus and relaxation. If something is bothering me at the start of a run, chances are I’ll forget about it by the end. I greatly enjoy all the scenery and experiences running in the mountains, from the scenic vistas to the encounters with wildlife. I love the trail running community, which is full of kind, determined and likeminded people.

Tell us about the challenges of the Eastern States 100.

The course features 20,000 feet of elevation gain through extremely technical terrain – amid August, no less. The humidity was intense, and staying on top of nutrition/hydration was a constant battle. The biggest challenge was the sleep deprivation towards the end. I just became so loopy and my morale started to crack. Luckily my crew and pacers kept me motivated.

How do you prepare?

I had to devote every minute of my free time to running. Every day after work I immediately had to stack miles. The weekends called for even longer days on the trails; often I would run back-to-back marathons on Saturday and again on Sunday. I also incorporated a lot of speed workouts, hill workouts and strength training.

Tell us about the sites you see as a runner.

I’ve had so many unique encounters with wildlife that some would never believe. I’ve run up on more bear than I can count, sometimes mothers and cubs. I’ve kicked up bobcats, coyotes, fishers, minks and other unique creatures you seldom get to see. I’ve stood at so many mesmerizing vistas that few people know about and even fewer make the journey out to see. I enjoy running by old foundations from a bygone era, seeing old Civilian Conservation Corps cabins, and running on old logging grades from the turn of the century.

Tell us about the community surrounding these events.

The community is the best part of trail running. Whether you are in first or last place, you are guaranteed thunderous applause during your race. People are so devoted to clearing trails and volunteering at aid stations – sacrificing so much of their time just to see these events continue to thrive. The community is just full of like-minded people who enjoy nature, work hard and love to have fun!

Day Job

McCoy also answered a few questions about his work for Advanced Powder Products Inc., a metal injection molding and metal 3D-printing company in Phillipsburg. Metal injection molding uses powdered metal with a polymer binder.

Is metal injection molding unique?

Metal injection molding is an industry that really began emerging as recently as the 1990s. While not nearly as common as plastic injection molding, it has grown to be over a $1.5 billion industry, as of 2015. While there are many contenders in the industry, APP separates itself by standing in the top ranks.

What are the advantages of this type of manufacturing?

Metal injection molding technology is able to deliver small, complex geometries that are mechanically superior to casted metal components, and nearly equal to that of parts machined from raw stock. Both processes mentioned are very expensive and time consuming, while MIM is able to produce hundreds of parts per hour.

What is your role?

I am responsible for injection molding development on every new mold that comes into the shop. With each new project, I am also responsible for designing and writing a corresponding robotic automation program. I am also responsible for installation and validation of all new injection molding and robotic equipment when it arrives.

What is cool about what you do?

APP grows by leaps and bounds annually and is always ahead of the curve with its technology. It's amazing to look back at where we were just a year ago and see how far we’ve grown and developed in such a short time. You are never locked into just one role and have the opportunity to learn new skills daily. We also make a wide range of extremely interesting products that cater to the defense, sporting goods, medical, dental and numerous other industries. It is very rewarding to walk into the sporting goods store and see components that you’ve developed on the shelf.

How did Penn College help you prepare?

Penn College is famous for its lecture-to-lab ratio. All of the time spent in class physically working with equipment gave me strong confidence and competency to start handling equipment on my first day of work. My time spent in lecture and learning the theory behind polymer processing gives me the ability to understand our process on a molecular level and solve complex problems that are not immediately apparent on the surface.

![Reagan McCoy '20 strides across a stream during the Eastern States 100. The 100-mile trail race features 20,000 feet of elevation gain. [Photo by Kevin Peragine Photography]](/sites/default/files/styles/medium_square/public/2024-02/2023-Eastern-States-100--Reagan-McCoy-661_2.jpg?itok=fi2q2SXp)

Share your comments

Penn College Magazine welcomes comments that are on topic and civil. Read our full disclaimer.

We love hearing from you