Radiographic Inspection for Non-Destructive Testing

About this program

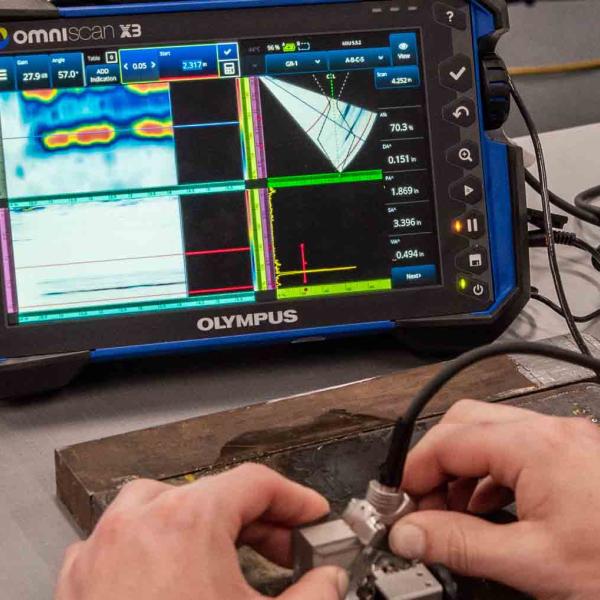

Dive into a cutting-edge program that prepares you to take the lead as a radiographic non-destructive test technician. In this fast-track program, you’ll learn how to evaluate the safety and durability of welds and metal parts using the latest radiographic technology. Working in specialized labs alongside faculty with real-world experience, you’ll get experience safely using X-ray and gamma ray radiation sources and exposure devices. Explore various industry radiographic inspection standards. And develop and evaluate inspection procedures for different radiation sources. After just five courses, you’ll be ready to pass the Industrial Radiography Radiation Safety Personnel (IRRSP) radiation safety test and prepared for a host of new career opportunities.

Career

Non-destructive testing with radiographic emphasis

Courses

At Penn College, we believe your educational experience should go beyond specialized skills. Real-world ready means taking a broader approach that builds communication skills, inspires collaboration, and encourages exploration of arts, history, and science.

Next steps...

You're on your way to becoming a tomorrow maker.

Tour Schedule

Seeing is believing.

Think Penn College might be a good fit for you? Make plans to visit and discover what hands-on learning is all about.

Jul 19

Undergraduate Open House

Saturday, July 199 AM - 3 PM

Oct 4

Undergraduate Open House

Saturday, October 49 AM - 3 PM

Nov 2

Undergraduate Open House

Sunday, November 29 AM - 3 PM

Industry Partners

Work with experts to become an expert

Penn College's strong partnerships impact every step of your journey – from your first day in the classroom and labs, to career placement (oftentimes before graduation) and beyond.

Career Fair Connections

Penn College graduates are in high demand. Employer participation at the Career Fair is proof. Attracting 400+ organizations, this popular event is hosted twice per year and introduces students to all types of businesses from startups to Fortune 500 companies.

Related Programs

Follow your passion

Student Life

Lead and put your skills to the test

American Welding Society (AWS)

Being a part of the AWS allows students to network and learn and sharpen the skills needed for a successful career in the welding industry.

SkillsUSA

Student Organizations at Penn College

Your college experience is about more than the classroom. Join one of 65+ clubs and organizations, or create your own.

Penn College News

Monday, April 7, 2025

Penn College student finds her calling in nondestructive testing

Wednesday, August 28, 2024

API donates standards to Penn College for academic programs

Thursday, April 4, 2024

Video shares exciting field of non-destructive testing

Student Experience

The community as their classroom

Penn College welding students cap unique remodeling project

Members of the college’s American Welding Society student chapter and faculty advisor recently volunteered their time and expertise to craft and install a 6-by-9-foot “tree of life” metallic sculpture at a former church.

More Information

- A competency credential must be completed within three years of enrollment in the credential.

- Non-traditional credit such as credit-by-exam, work/life experience, and transfer credit is limited to one third of the total credits in the credential. Two thirds of the requirements must be completed by course enrollment.

- Students must earn a grade of ‘C’ or better in each course to merit the credential.

Alternative Credit refers to academic credits earned through means other than traditional college course completion, including: credit by exam, articulation, proof of competency gained in high school, work/life experience, and advanced placement.

Visit the Alternative Credit Options page for requirements and procedures and for information on credit through Advanced Placement.

Tools

Students should review the Welding Tools & Supplies to determine what tools and supplies they will need to purchase. The Welding department realizes that some students may not need to purchase the entire list of supplies. These students may contact the School Office for guidance in purchasing their supplies. The College Store can provide the complete kit.

Personal Protection Equipment

- Leather work shoes (safety toes optional)

- Safety glasses

- Welding helmet with #10 lens

- Cutting goggles with #5 lens

- Welding jacket

- Welding gloves (SMAW & GTAW)

Personal Protection Equipment and tools are available for purchase through The College Store .

- Mr. Dan Bechek, Sales Engineer / Central PA, Lincoln Electric

- Mr. Robert Blauser, '96, '00, Vice President of Operations, GSM Industrial

- Mr. Richard A Conrad, Jr., '02, Field Application Engineer, Hobart/Miller Electric

- Mr. Jacob D Fisher, '10, Plant Manager, High Steel Structures LLC.

- Mr. Eric F Geier, '17, Operations Leadership Rotation Future Leader, Aerojet Rocketdyne

- Mr. Matthew Hillyer, Welding Engineer, Johnson Controls Navy Systems

- Mr. Wayne A Leone, Welder Training & Testing for Susq. Nuclear Power Plant, PP&L

- Mr. Michael Sebergandio, '01, '03, Quality Engineer - Welding, Case New Holland

- Mr. Brian A Thompson, Owner, Jasper Steel Works, LLC

- Mr. Richard Wagoner, Principal Construction Training Leader, UGI Utilities